Introduction to Signal Conditioners

Signal conditioners play a key role in processing signals for various devices. They ensure that signals are accurate, compatible, and reliable, enabling systems to function seamlessly.

Definition and Purpose of Signal Conditioners

Signal conditioners are devices used to modify signals for optimal processing and interpretation. They adjust the signal properties like voltage, current, or frequency to match the requirements of connected devices. The main goal is to ensure accurate communication between sensors and control systems. Additionally, they protect against noise, distortions, and interference during signal transmission.

Importance of Signal Conditioning in Industrial Applications

Signal conditioning is essential for accurate and efficient operations in industrial environments. In manufacturing, it helps ensure precise measurements from sensors. In automation systems, properly conditioned signals improve control and monitoring accuracy. Reliable signaling reduces errors, boosts productivity, and enhances overall system performance. Moreover, it minimizes costly downtime and maintenance caused by signal issues.

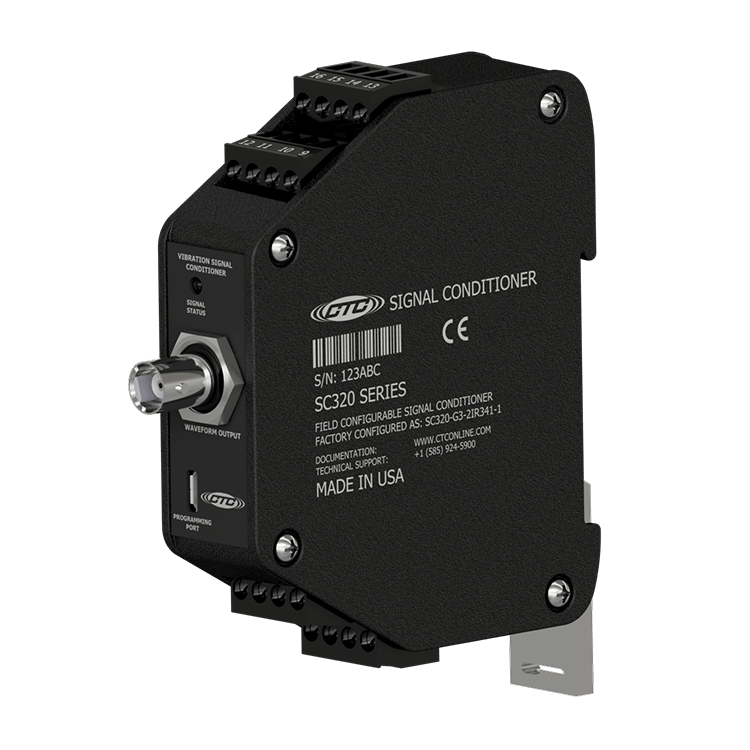

Types of Signal Conditioners

Signal conditioners come in various types, designed to meet specific signal processing needs. Each type offers unique features and applications, enabling optimized performance in diverse environments.

Analog Signal Conditioners

Analog signal conditioners process analog signals from devices like sensors and transducers. They adjust voltage, current, or resistance for compatibility with control systems. Common functions include amplification, filtering, and signal isolation. Analog conditioners are ideal for environments needing continuous and real-time data.

Digital Signal Conditioners

Digital signal conditioners optimize and process digital signals for electronic systems. These conditioners convert analog signals to digital formats for easier interpretation by microcontrollers or computers. They ensure high precision and robustness in signal processing. Digital signal conditioners are often used in automation and computer-based applications.

Wireless Signal Conditioners

Wireless signal conditioners transmit signals wirelessly between devices without physical connections. They enhance flexibility and simplify installations in complex environments. These conditioners are useful in remote monitoring, IoT applications, and systems requiring mobility or scalability. Wireless signal conditioners minimize wiring challenges while maintaining signal clarity.

Key Components of Signal Conditioner

Signal conditioners rely on specific components to process signals effectively. These components ensure accurate and reliable signal conditioning.

Amplifiers and Filters

Amplifiers increase weak signal strength for better processing. Filters remove unwanted noise and frequency interferences. These components ensure signals remain clear and precise. Precision in measurement and data reliability depends on effective amplification and filtering.

Isolation and Conversion Modules

Isolation modules prevent electrical interference between devices. They protect equipment and improve safety by isolating signal paths. Conversion modules change signals into the required formats, such as voltage-to-current conversion. These modules ensure compatibility between devices with different communication standards.

Calibration Instruments

Calibration instruments maintain the accuracy of signal conditioners. They adjust components to deliver consistent and error-free measurements. Regular calibration prevents drift in signal accuracy over time. It also ensures signal conditioners meet stringent performance standards in various applications.

Applications of Signal Conditioner

Signal conditioners enhance performance across various industries. Their role spans automation, power monitoring, and sensor data systems.

Process Control and Automation

Signal conditioners ensure precise control in process automation. They convert and adjust signals from sensors. This supports accurate data interpretation by control systems. In manufacturing, they enable reliable operations and reduce errors. By filtering noise, they maintain smooth system performance. Signal conditioners are key to achieving process consistency in industrial setups.

Electrical and Power Monitoring

In electrical systems, signal conditioners monitor power flow and quality. They analyze signals from voltage or current sensors. This helps identify potential issues, like fluctuations or faults. Reliable power monitoring protects equipment and reduces downtime. Signal conditioners also enhance the precision of energy management systems. This ensures efficient distribution and reduced energy waste.

Sensor Data Acquisition Systems

Signal conditioners optimize data from diverse sensor types. They adjust signals for compatibility with data acquisition devices. By amplifying weak signals and filtering noise, they improve measurement accuracy. These conditioners are vital in fields like medical diagnostics and environmental monitoring. They ensure sensors deliver consistent, high-quality data for critical decisions.

Benefits of Signal Conditioner

Signal conditioners provide several crucial benefits to ensure effective signal processing and system performance. These advantages contribute to their widespread use across industries.

Improved Accuracy and Reliability of Measurements

Signal conditioners improve the accuracy of measurements by removing signal distortions and noise. They amplify weak signals, ensuring better precision during data transmission. By stabilizing different signal types, they improve repeatability and consistency. These features are vital for industries where precision is a top priority, like healthcare and manufacturing.

Enhanced Compatibility Between Devices

Signal conditioners adjust signals to ensure compatibility between different devices. They convert signals into formats that match the requirements of connected systems. This feature eliminates errors caused by mismatched signals and ensures smoother communication. Enhanced compatibility simplifies complex system integrations and boosts operational efficiency.

Protection Against Noise and Interference

Noise and interference can distort signals and lead to errors. Signal conditioners filter and isolate signals to protect against these issues. Isolation modules shield sensitive devices from electrical interference, ensuring system safety. Filters improve signal clarity by removing unwanted frequencies, preserving data integrity. These protections are vital for systems operating in harsh environments or with sensitive equipment.

How to Select the Right Signal Conditioner

Choosing the right signal conditioner is crucial for effective signal processing. It ensures optimal performance, reliability, and system compatibility. By evaluating specific requirements and available options, you can make an informed decision.

Factors to Consider: Signal Type, Environment, and Budget

- Signal Type: Identify the type of signal you need to process. Determine if it’s analog, digital, or wireless. This step ensures compatibility with your system’s sensors and devices.

- Environment: Evaluate the operational environment. Harsh conditions may require rugged, durable signal conditioners. Consider factors like temperature, humidity, and potential interferences during signal transmission.

- Budget: Analyze the cost against your requirements. Select a model within your budget that doesn’t compromise on quality. Balance initial costs with long-term maintenance needs for better investment value.

- Features Needed: Look for specific features like signal amplification, filtering, or isolation. Ensure the device offers the functionalities required for your system.

- Ease of Integration: Verify that the signal conditioner integrates seamlessly with your existing equipment. Simpler integration reduces time and efforts during installation.

Comparison Between Top Brands and Models

- Performance & Specifications: Compare the technical specifications of different brands. Check parameters like accuracy, input/output range, and signal conversion efficiency.

- Reliability & Durability: Opt for brands known for consistent performance. Choose models built for long-term use.

- Customer Support: Evaluate the after-sales support provided by manufacturers. Brands offering quality technical support ensure smooth troubleshooting.

- User Reviews & Feedback: Read user reviews and case studies. They often highlight real-world performance of specific models in various industries.

- Customizability: Explore models that allow parameter customization. Customizable options provide flexibility for unique system requirements.

By carefully assessing these factors and comparing brands, you can select a signal conditioner that meets your application needs while ensuring reliability and efficiency.

Installation and Maintenance Tips

Proper installation and maintenance of signal conditioners ensure efficient and reliable operation. Following best practices can help avoid errors and extend the device’s life.

Proper Wiring and Configuration Guidelines

- Match Wiring Specifications: Use cables compatible with the signal conditioner’s requirements to ensure proper operation.

- Organize Wiring Neatly: Group and label cables to avoid confusion and simplify troubleshooting.

- Minimize Signal Interference: Separate power cables from signal cables to reduce noise and interference.

- Follow Manufacturer Instructions: Adhere to installation guides for accurate configuration and setup.

- Check Connections Thoroughly: Verify all electrical connections for secure and error-free communication.

Regular Testing and Calibration Practices

- Perform Routine Tests: Test the signal conditioner regularly to identify potential issues before they escalate.

- Calibrate at Scheduled Intervals: Adjust components periodically to maintain signal accuracy and consistency.

- Use Calibration Tools: Employ specialized instruments for high precision during calibration.

- Check for Drift: Monitor signal accuracy and correct deviations promptly.

- Document Maintenance: Keep records of calibration and testing to track performance trends over time.

By following these guidelines, you can optimize the operation of signal conditioners and ensure longevity.

Advances in Signal Conditioning Technology

Integration with Smart Technologies

Recent advancements in signal conditioning technology are making these devices smarter and more efficient. The integration of Internet of Things (IoT) capabilities allows signal conditioners to collect and transmit data in real time. This development is particularly valuable in industrial settings, where immediate data analysis can lead to improved operational decisions. Smart signal conditioners may offer features like remote monitoring, which allows users to track performance from anywhere. This added functionality not only enhances user experience but also delivers significant improvements in system efficiency.

Use of Digital Signal Processing

The introduction of digital signal processing (DSP) has transformed how signal conditioning is approached. DSP allows for advanced filtering techniques and precise adjustments to be made to signals. This technology can significantly reduce noise interference and improve overall signal quality. By utilizing algorithms, digital signal conditioners can perform complex tasks that analog systems cannot achieve. This shift from analog to digital processing represents a major leap in signal conditioning capabilities and opens up new possibilities in various applications.

Miniaturization and Portability

Another significant trend in signal conditioning is miniaturization. Modern applications often require compact devices that can be easily integrated into existing systems. Small signal conditioners are more portable and can fit into tight spaces, providing flexibility for users. The development of microelectronic components has made it possible to create lightweight, powerful signal conditioning solutions without sacrificing performance. This trend is particularly important for mobile and handheld devices that demand efficient operation without the bulk.

Enhanced User Experience through Interfaces

The user experience is a critical aspect of modern signal conditioning systems. Many new models come equipped with intuitive interfaces that simplify operation. These interfaces may include touchscreen controls, customizable displays, and easy-to-navigate menus. Additionally, user-friendly software helps streamline configuration and monitoring processes. Enhanced interfaces ensure that users can easily access important data and settings, improving the overall functionality of signal conditioners. As technology continues to evolve, user experience will remain a focal point in the development of these devices.

Exploring Niche Applications for Signal Conditioners

Specialized Industries and Signal Conditioning

Signal conditioners find applications in various niche industries, each with unique requirements and challenges. For instance, in the aerospace sector, signal conditioners are critical for processing data from sensors that monitor temperature, pressure, and vibration in aircraft systems. High reliability and precision are paramount in this field, necessitating advanced signal conditioning techniques. Similarly, the automotive industry utilizes signal conditioners to enhance the performance of onboard sensors for engine diagnostics, safety systems, and infotainment. In these specialized applications, tailored solutions for signal conditioning help to ensure that systems operate optimally, enhancing safety and performance.

Research and Development

Research and development in the field of signal conditioning are continuously expanding. Innovations in materials science, electronics, and software are paving the way for smarter and more efficient signal conditioners. For example, the integration of artificial intelligence (AI) could allow for real-time data analysis, leading to automatic adjustments that optimize system performance. This ongoing R&D phase reflects a commitment to improving the technology and meeting evolving market demands. As industries grow and adapt, the role of signal conditioners will undoubtedly expand, opening up new opportunities for enhanced functionality and innovation.

Conclusion: The Future of Signal Conditioning

Preparing for a Technological Shift

As we look to the future, preparing for changes in signal conditioning technology is essential. The continuous advancements in smart technology and digital processing will undoubtedly shape how signal conditioners operate. Keeping pace with these changes will enable industries to adopt innovative solutions that enhance efficiency and reliability. Businesses and individuals should stay informed about new developments in signal conditioning to make the most of these advancements.

Recognizing the Need for Adaptability

Adapting to new signal conditioning technologies is critical for success. As systems become more complex, the need for advanced signal processing will only increase. Understanding your specific application requirements will help in selecting the right technology. Flexibility in approach and a willingness to embrace new methods will position users for success in a rapidly evolving landscape.

Commitment to Excellence

Ultimately, the importance of signal conditioners cannot be understated. These devices play a crucial role in ensuring data accuracy and integrity across various applications. A commitment to excellence in engineering, design, and functionality will drive the future of signal conditioning. By prioritizing quality and performance, industries can continue to rely on signal conditioners to support their technological advancements successfully.

Emphasizing a Collaborative Approach

The future of signal conditioning will also benefit from collaboration among manufacturers, engineers, and end-users. Open communication will lead to improvements in design, performance, and user needs. By working together, stakeholders can create signal conditioning solutions that meet the challenges of tomorrow. Emphasizing collaboration will help foster innovation and ensure that the technologies continue to evolve, providing valuable support across multiple industries.